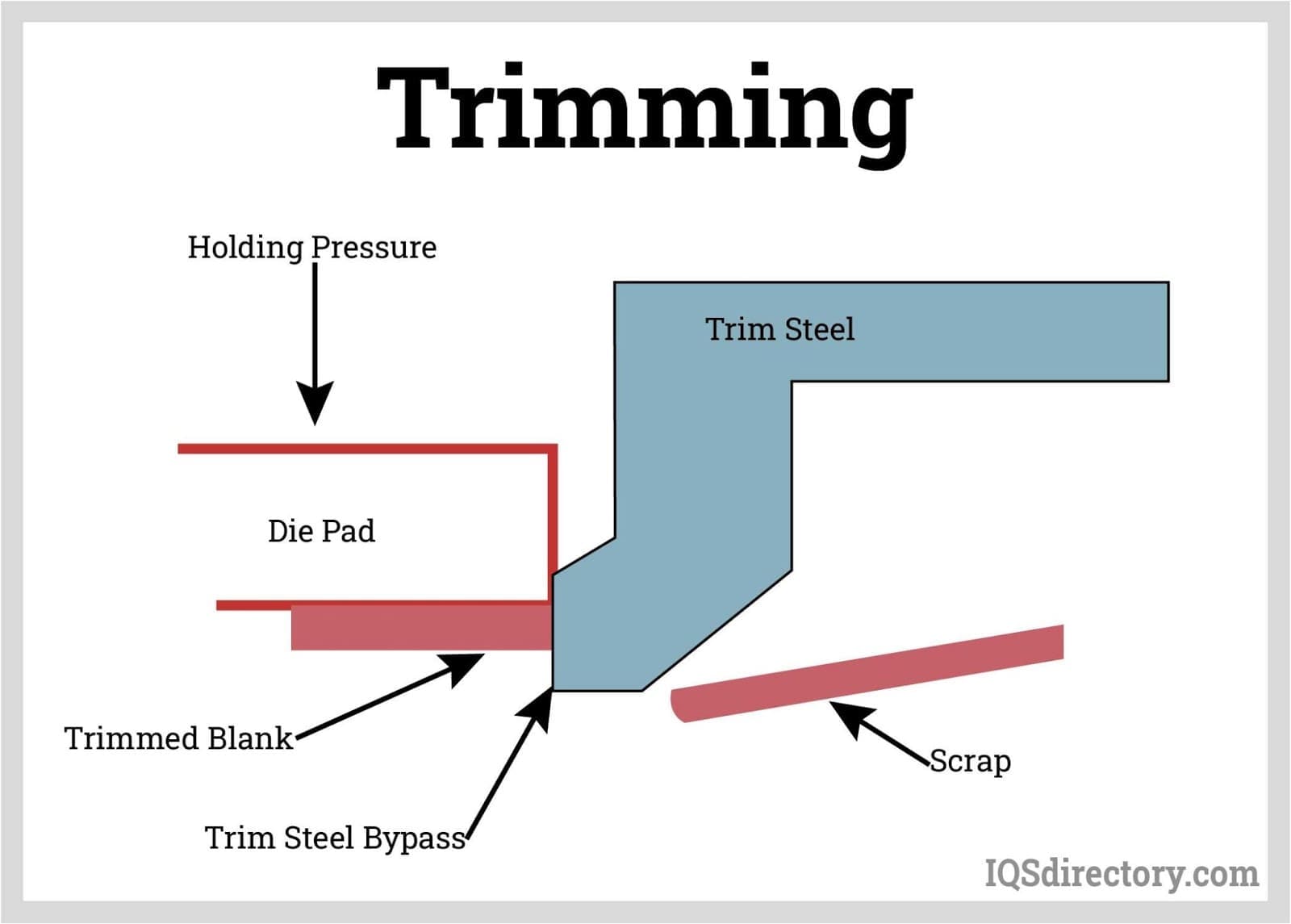

Trimming Sheet Metal - Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Following are the 9 different types of sheet metal operations: We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. It is cut in a straight line across a strip, sheet, or bar. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed.

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. It is cut in a straight line across a strip, sheet, or bar. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Following are the 9 different types of sheet metal operations:

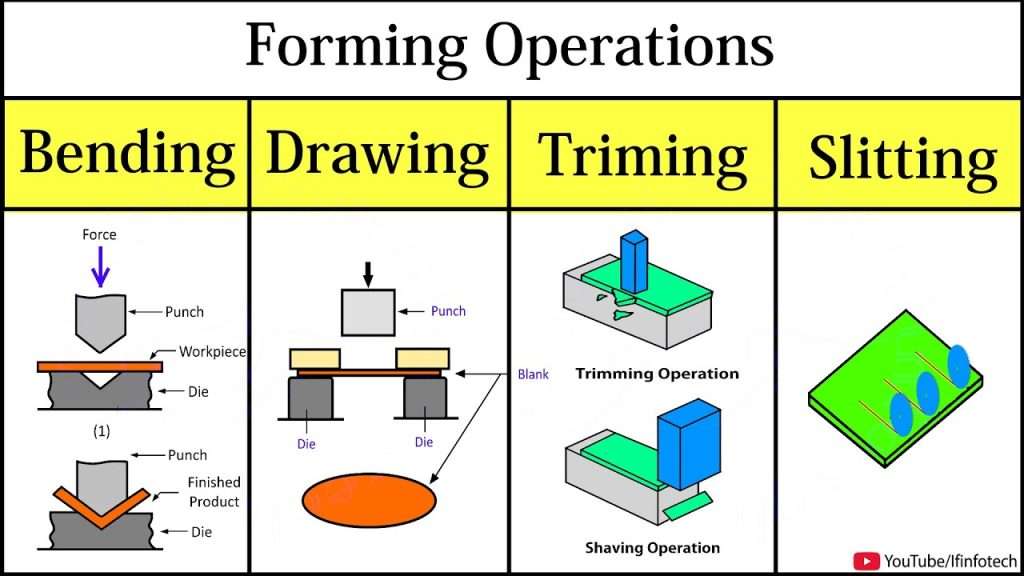

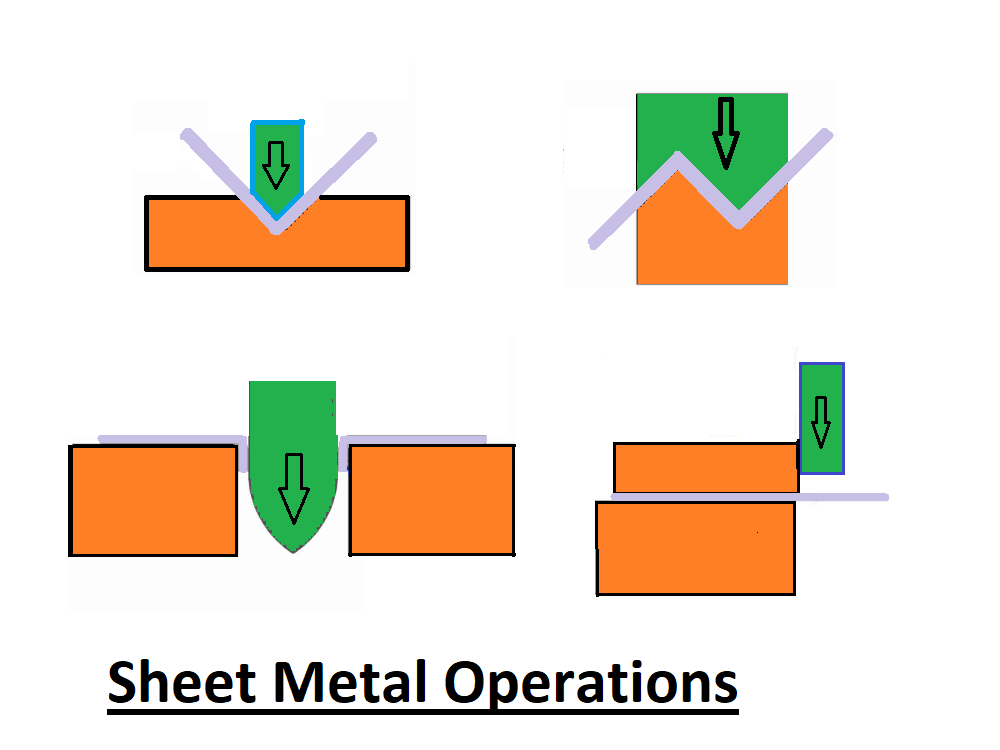

Following are the 9 different types of sheet metal operations: We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It is cut in a straight line across a strip, sheet, or bar. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed.

A Comprehensive Guide of Trimming Process CNC Machining Service

It is cut in a straight line across a strip, sheet, or bar. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. Following are the 9 different types of sheet metal operations:.

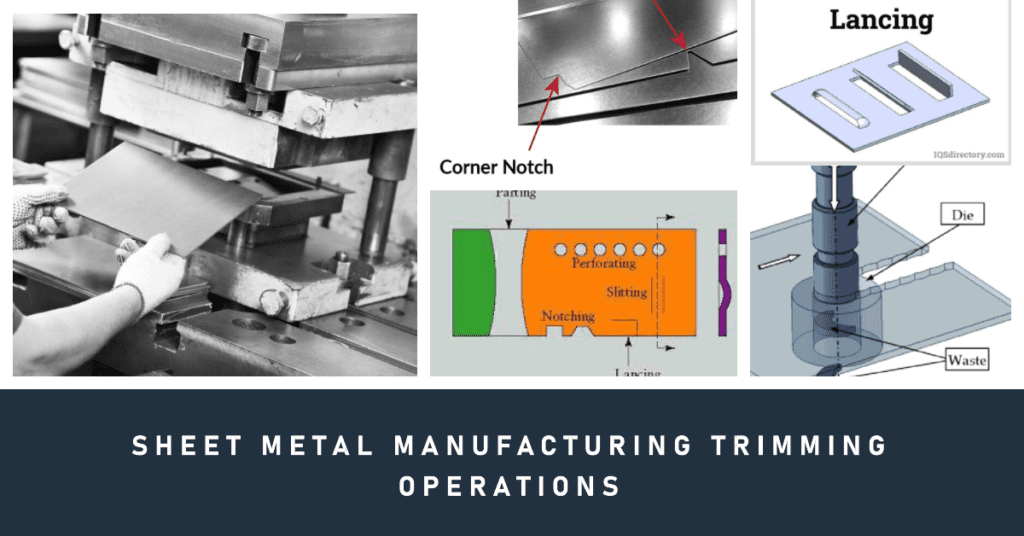

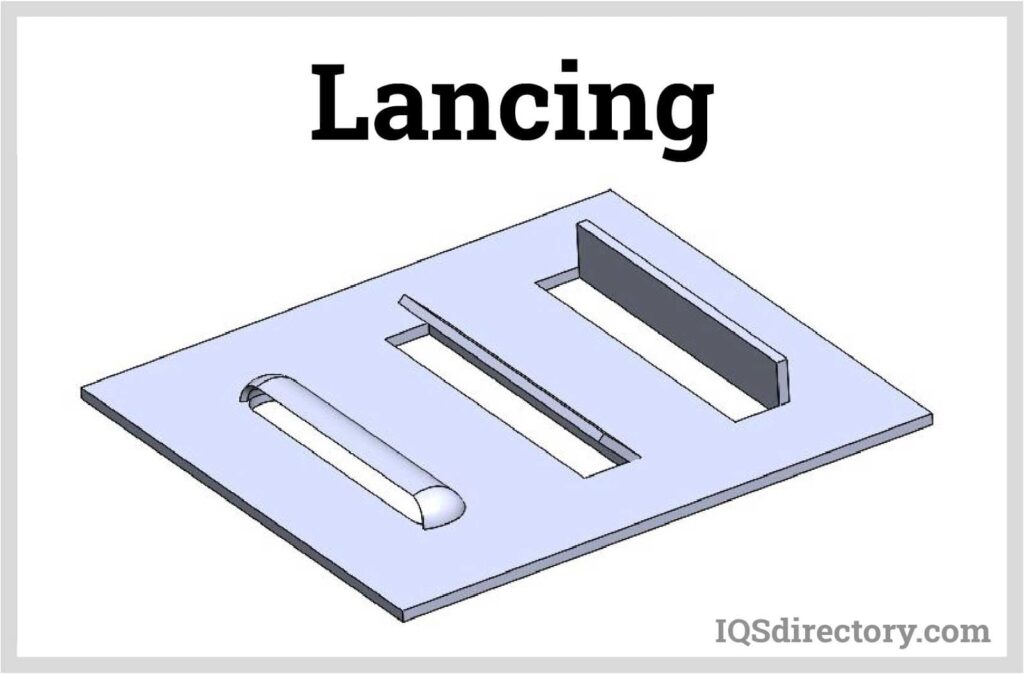

Different Types of Trimming Operations in Sheet Metal Manufacturing

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Following are the 9 different types of sheet metal operations: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. We want to talk about 12 different ways to cut sheet metal, both.

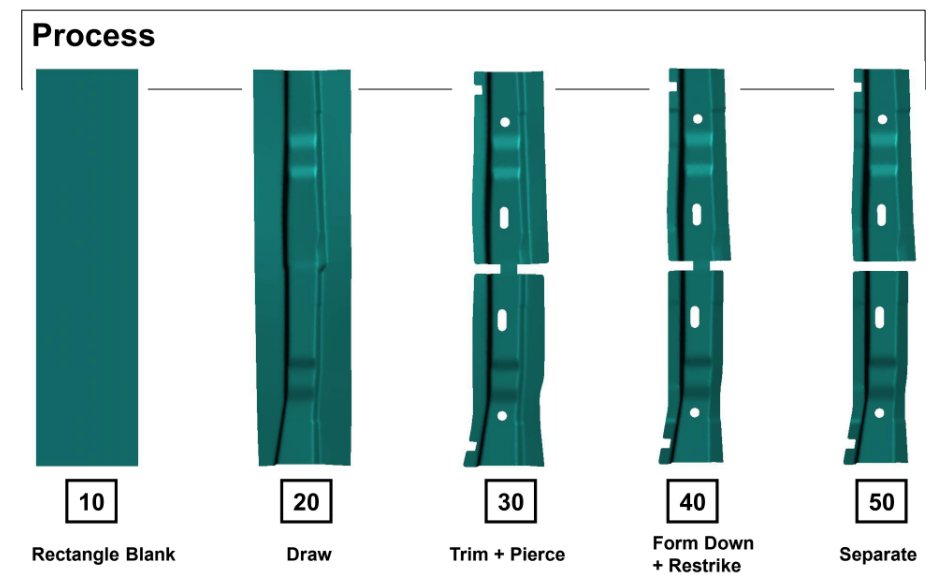

Metal Stamping What Is It? How Is It Used? Types Of

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It is cut in a straight line across a strip, sheet, or bar. Following are the 9 different types of sheet metal operations:.

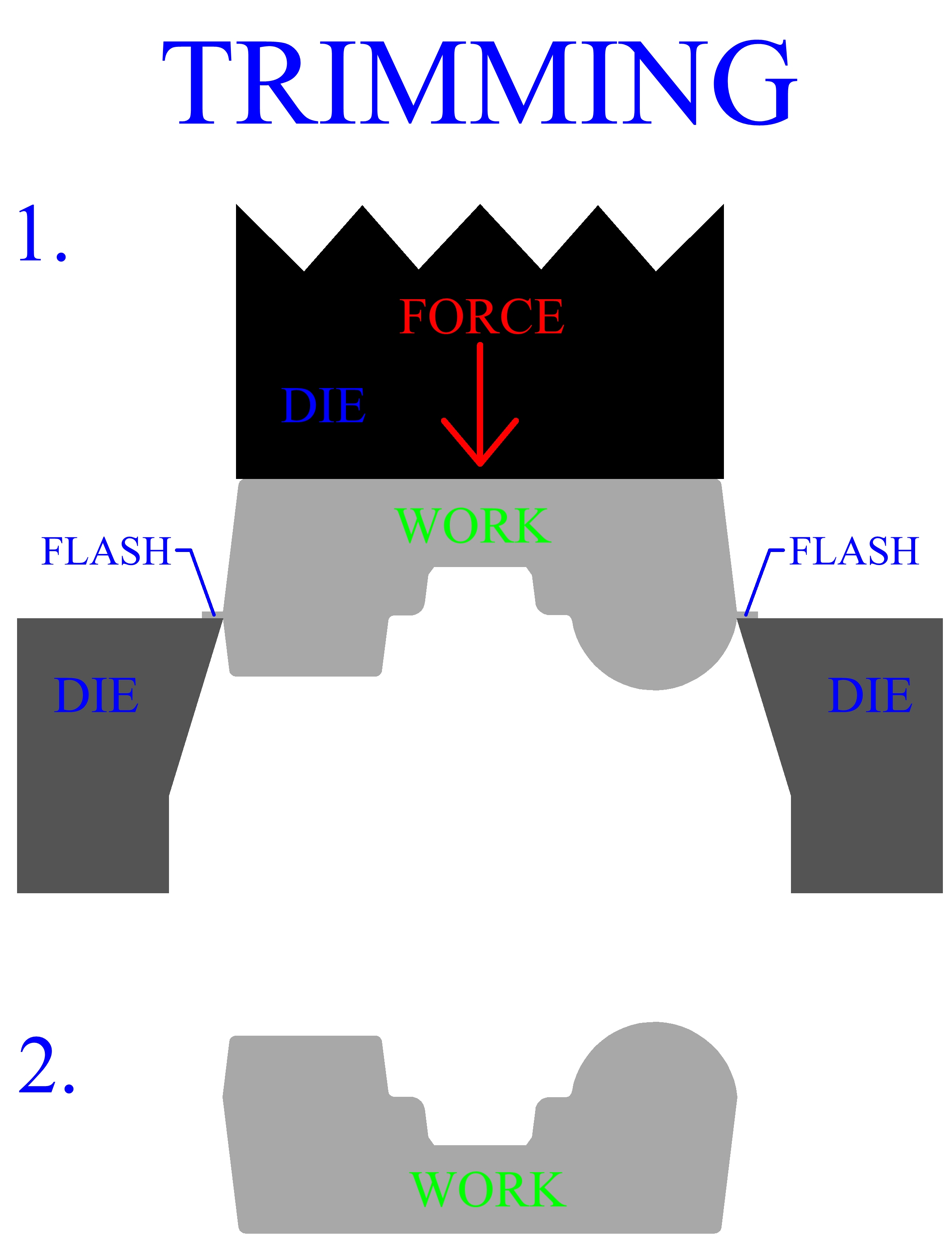

Trimming Of Parts

We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Following are the 9 different types of sheet metal operations: It is cut in a straight line.

Processes and Steps for Die Stamping

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. It is cut in a straight line across a strip, sheet, or bar. Trimming is a critical.

Different Types of Sheet Metal Operations with Diagrams GuideByTips

Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. Following are the 9 different types of sheet metal operations: In the realm of sheet metal manufacturing, trimming.

Improve Your Sheet Metal Trimming Process Through Simulation

We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. It is cut in a straight line across a strip, sheet, or bar. Following are the 9 different types of sheet metal operations: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and.

Trimming obtained by processing the edges of galvanized sheet metal

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Following are the 9 different types of sheet metal operations: Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. It is cut in a straight line across a strip, sheet, or bar..

Different Types of Trimming Operations in Sheet Metal Manufacturing

Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. Following are the 9 different types of sheet metal operations: It is cut in a straight line across.

TRIMMING SHEET METAL OPERATION ANUNIVERSE 22 YouTube

In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product. We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure.

It Is Cut In A Straight Line Across A Strip, Sheet, Or Bar.

Following are the 9 different types of sheet metal operations: We want to talk about 12 different ways to cut sheet metal, both with power tools and without power tools, so let’s figure out. In the realm of sheet metal manufacturing, trimming is a shearing process that removes excess material from a formed. Trimming is a critical process in sheet metal manufacturing, ensuring precision, efficiency, and smoothness in the final product.